Automatic transport lines and sorting stations are substantial components for the rationalization of the window production.

Automatic transport ´lines and sorting stations

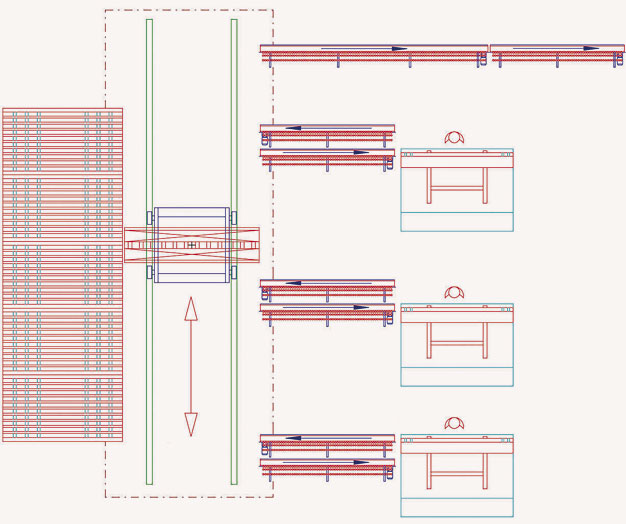

Frame-assembly line with a horizontal transport of the parts.

The feeding of the frames from the welding-cleaning lines to the connecting point. The frames are transported on two levels. Mounting stations for transoms and profiles are integrated, which are supplied constantly. Frames, that are fed small transoms or additional profiles go directly along the lower level to the next work station. This is the same for elements that come from the mounting stations. At the end of the line there is the frame mounting station RM 4000 and a tilt table for hanging up the sashes.

Work stations for the mounting of transoms and additional profiles on a two-level transport line.

Whether one, two or several transoms have to be built in or few or many profiles have to be mounted – independent working is in any case possible at all work stations.

The continuous production with integrated mounting aisles.

For a cycle-time independent frame processing.![]()

Sorting – and feeding systems for elements into the glazing lines –

with a Buffer shelf and an automatic distribution trolley. The windows are glazed and afterwards palletized in perfect order according to each assignment.

Leaf sorting station

The readily attached leafs are automatically straightened up and staged in a shelf to be hung up.